ODM Customization Expert

Advanced Production & Processing Equipment

Longwan Machinery has a variety of advanced domestic and foreign molding equipment, including 2 fully automatic production lines for clay sand, 1 semi-automatic production line for clay sand, and 1 coated sand production line, with an annual production capacity of 15,000 tons.

Complete Inspection Flow

Strict Quality Inspection

We have full-process testing equipment: spectrum analyzer, metallographic microscope, universal tensile testing machine, magnetic particle flaw detector, ultrasonic flaw detector, etc.

The above equipment can fully ensure that we can provide customers with high-precision final castings, and at the same time ensure that we meet customers' comprehensive testing requirements for physical and chemical properties of materials, non-destructive testing, high-precision geometric dimension testing, etc.

Professional Casting Expert

Comprehensive Casting Manufacturer

-

QWhere are your products mainly exported to?A

Our products are mainly exported to multiple countries such as Germany, Japan, Italy, South Korea, and Australia.

-

QHow to deliver the goods to us?A

Usually, we ship by sea, which is very convenient for export.

Of course, if the customer's goods are urgent, we can also air freight them. Ningbo Airport and Shanghai International Airport are both very close to us.

-

QWhat's the payment term?A

When quoting, we will confirm the transaction method with you.

For mass production, we usually make a 50% advance payment in advance and then inspect and confirm the shipment before paying the remaining balance.

-

QHow to guarantee the quality of your goods?A

Firstly, there will be corresponding inspections after each process, and for the final completed product, we will conduct a full inspection according to customer requirements and international standards;

Then, we have advanced and complete top testing equipment in the industry: spectral analyzers, metallographic microscopes, universal tensile testing machines, magnetic particle testing machines, ultrasonic testing machines, etc.

The above equipment can fully ensure the provision of high-precision final castings to customers, while also meeting the comprehensive testing requirements of customers for material physical and chemical properties, non-destructive testing, high-precision geometric dimension testing, and so on.

-

QHow many employees of your company? what about the technicists?A

Our company has more than 120 employees, including 10 professional technicians and 5 engineers.

-

QHow about the capacity of your company?A

We have 2 fully automatic clay sand production lines, 1 semi-automatic clay sand production line, and 1 coated sand production line, with an annual production capacity of 15000 tons.

-

QDo you have some standard parts?A

No, currently we produce and customize according to the requirements based on the drawings provided by the customer.

-

QCan you do customized products?A

Yes, we are mainly doing customized products according to the customers’ drawings or samples.

-

QWhat applications do your products relate to?A

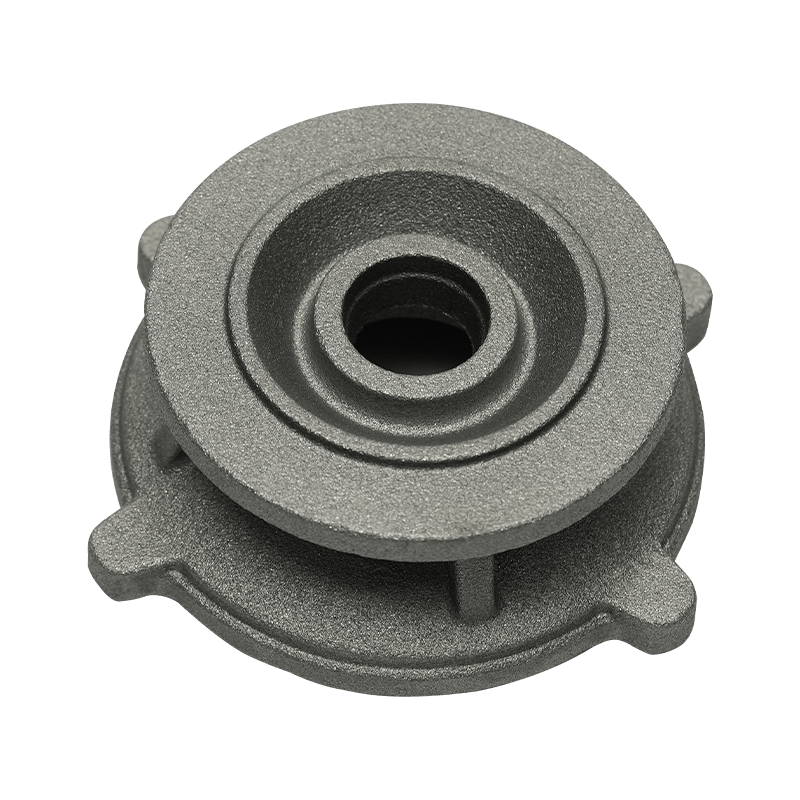

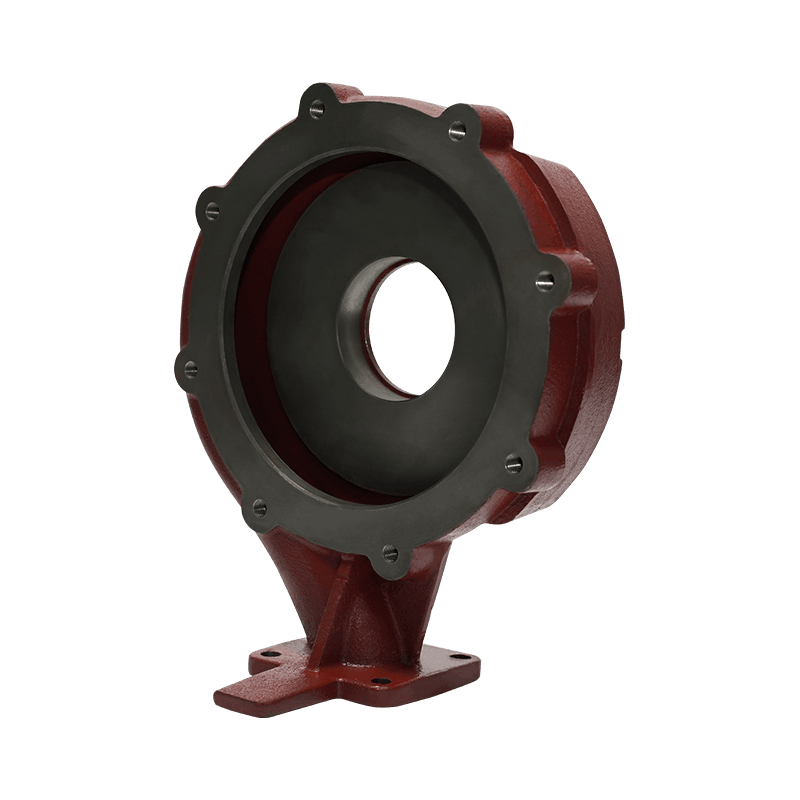

Our products cover almost all the applicable equipment manufacturing and machinery manufacturing and processing fields, mainly including automotive trucks, engineering machinery, agricultural machinery, reducers, water pumps, water treatment systems, and other fields.

-

Qwhat products can you offer?A

We mainly produce cast iron parts made of gray cast iron and ductile iron materials.

-

QAre you a direct manufacturer or trading company?A

We are a foundry and a manufacturer of cast iron parts.

-

QHow long can I get the feedbacks after we sent the inquiry?A

We will reply to you within 24 hours of the working day.

-

How Ductile Cast Iron Reducer Accessories Improve Gearbox Performance

In modern industrial applications, gearboxes are essential components that enable the transfer of mechanical power across machines, ensuring smooth op...

READ MORE -

How Ductile Cast Iron Agricultural Machinery Parts Improve Efficiency in the Field

In the world of modern agriculture, machinery plays a vital role in increasing productivity, improving crop yields, and reducing labor costs. As farmi...

READ MORE -

Improving Safety and Durability with Ductile Cast Iron Automotive Parts

The automotive industry continually seeks ways to improve vehicle performance, safety, and durability. One material that has significantly contributed...

READ MORE -

Ductile Cast Iron vs. Traditional Cast Iron: What You Need to Know

When it comes to materials used in industrial applications, two types of cast iron are often compared: ductile cast iron and traditional cast iron. Bo...

READ MORE

English

English русский

русский Deutsch

Deutsch